Eagle Barton Oxide Systems

Quality Oxide From the Oxide Equipment Experts!

Lead acid battery performance is dependent upon the quality of lead oxide used. This is why Eagle’s Barton oxide systems have been designed to produce a wide range of high quality oxides for a wide range of battery types.

Three systems to choose from depending upon your production needs:

350 to 450 Kg/Hr

700 to 900 lbs/Hr (10-Ton/Day)

750 to 950 Kg/Hr

1600 to 2000 lbs/Hr (24-Ton/Day)

1000 to 1200 Kg/Hr

2200 to 2600 lbs/Hr (30-Ton/Day)

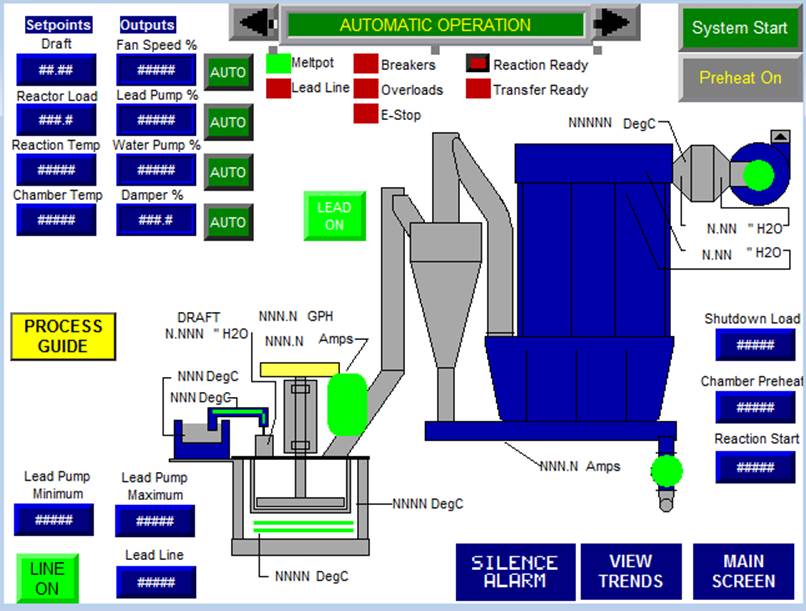

Our mechanical and electrical control systems automatically control and maintain critical operating conditions to ensure oxide quality meets specifications. With Eagle’s unique temperature monitoring and PLC control algorithms; our systems easily allow operators to produce a selected ratio of tetragonal PbO crystal structures, ranging from 70% to 99% with very little variability.

OXIDE SPECIFICATIONS

Total PbO

Total Free Lead

Apparent density

Acid Absorption

Tetragonal crystal of PbO

Particle Size

68 to 82%

18 to 32%

1.2 to 1.8 g/cm3

160 to 210 mg/g

70 to 99%

3.5 to 4.5 micron

Environmental conditions and ease of use for the operator are demanding elements in any processing equipment. Eagle understands these requirements and has developed a control system that provides operators with single Start-Up and Shut-Down buttons for the entire system. The control also monitors multiple sensors and will automatically shut down the system and alert the operator of any critical issue. Cost of operation is always a consideration in any equipment purchase and Eagle’s Barton systems are the most efficient in the industry.

The following chart indicates energy consumption of key components of the system and overall average per hour during normal operation.

Lead Melt Pot

Reactor Pre-Heat

Electric Motors in System

Water Feed System

Avg. Consumption/Hr*

EOS 500

30 kW

33 kW

45 kW

50 liters/hr max.

45 kW

EOS 1000

60 kW

63 kW

55 kW

75 liters/hr max.

90 kW

EOS 1200

75 kW

63 kW

65 kW

100 liters/hr max.

110 kW

Eagle’s knowledge of lead oxides and equipment design and build makes us a leading expert to assist customers in selecting the best system for the battery type to be produced. This knowledge along with a dedicated team of support staff will carry on the Eagle tradition of superior assistance after installation and start-up to ensure your operation meets all requirements.

The Eagle Advantage

- Support From The Global Experts in Oxide Manufacturing & Handling Equipment

- Superior Control Systems – One-Button Start-Up & Shutdown

- Designed To Protect The Environment

- Quality Materials & Construction For Years Of No-Hassle Service

Experience why the world’s leading battery manufacturers use Eagle equipment and systems. Contact Eagle Today!